Fused silica is formed by chemical combination of silicon and oxygen. Advantages of fused silica material include good UV and IR transmission, low thermal expansion, providing stability and resistance to thermal shock over large temperature excursions, wider thermal operating range and high laser damage threshold.

|

|

Capability:

|

Attribute

|

Commercial

|

High Precision

|

|

Material

|

UV grade Fused Silica

|

|

Typical Diameter (mm)

|

5, 10, 12.7, 25.4, 30, 50

|

|

Typical Thickness (mm)

|

1, 2, 3, 6, 10

|

|

Diameter Tolerance

|

+0.0, -0.2mm

|

+0.0, -0.1mm

|

|

Thickness Tolerance

|

±0.1mm

|

±0.01mm

|

|

Parallelism

|

<1 arc minute

|

<10 arc seconds

|

|

Surface Quality

|

40-20 scratch and dig

|

20-10 scratch and dig

|

|

Wavefront Distortion

|

λ/4 per 25mm @ 632.8nm

|

λ/10 per 25mm @ 632.8nm

|

|

Protective Bevel

|

0.1 - 0.5mm × 45°

|

0.05 - 0.2mm × 45°

|

Note: Other sizes and coatings are available upon request.

High Precision Fused Silica Windows

|

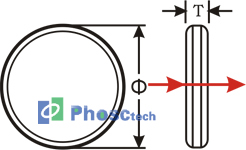

Diameter(mm)

|

T(mm)

|

1′Parallelism

|

10" Parallelism

|

|

Part No

|

Part No

|

|

12.7

|

6.0

|

WIN1220

|

WIN1221

|

|

25.4

|

6.35

|

WIN2520

|

WIN2521

|

|

30.0

|

6.0

|

WIN3020

|

WIN3021

|

|

50.0

|

10.0

|

WIN5020

|

WIN5021

|